Last Thursday, CP Aluart took part in the International Markets Conference, organized by the Barcelona…

Promoting innovation and sustainability in knitwear

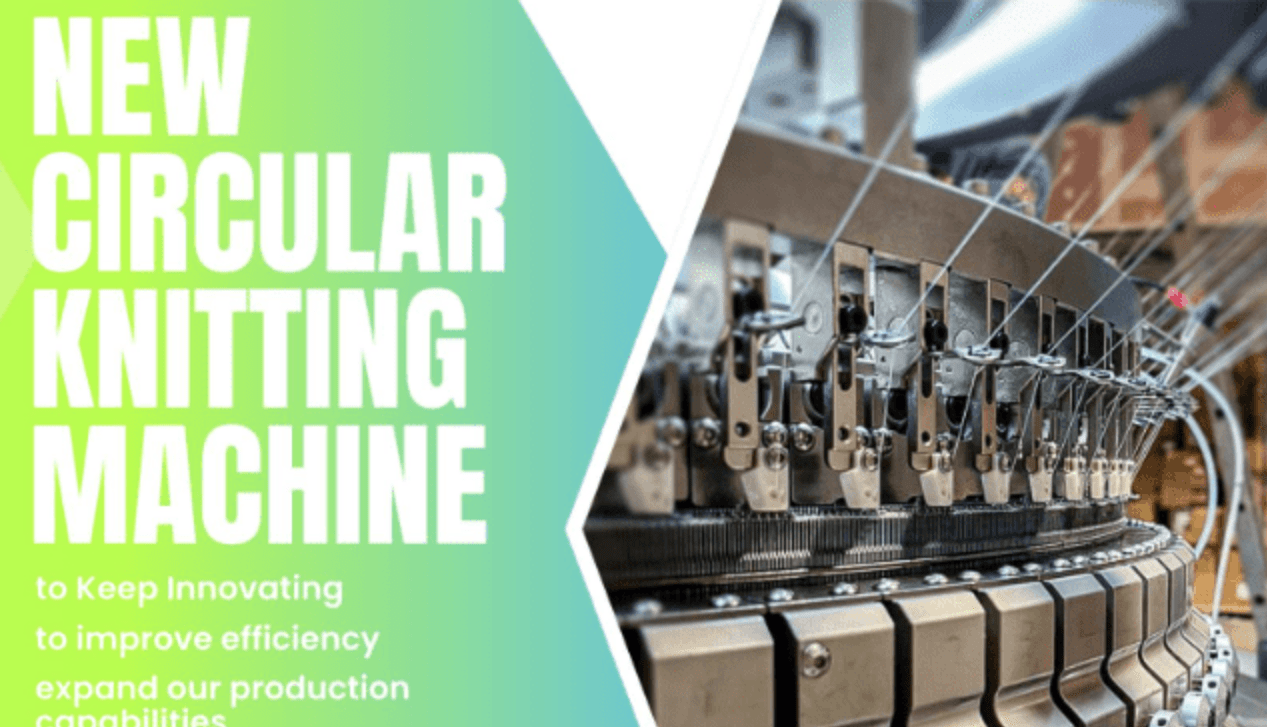

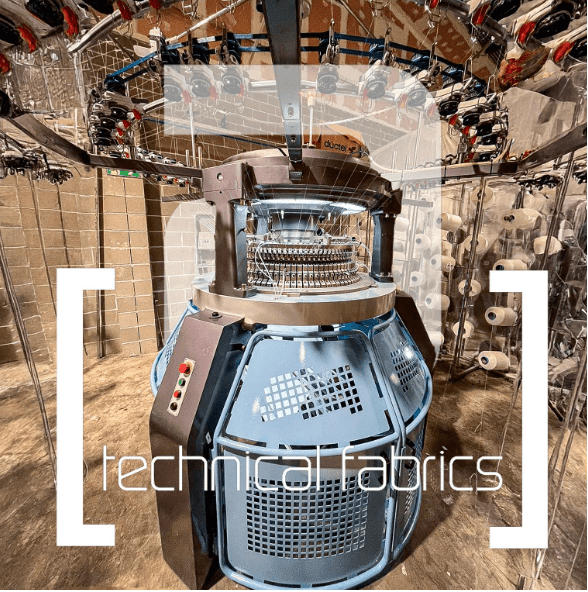

At CP Aluart, we continue to invest in technological innovation. We are pleased to announce the acquisition of a state-of-the-art circular knitting machine, a new piece of equipment to enhance our specialization in the production of technical circular knit fabrics. This type of fabric, essential in multiple sectors, can now be produced with greater precision, efficiency, and quality thanks to this new addition.

Circular knit fabric not only stands out for its technical characteristics but also aligns with the sustainability and local economy values we promote at CP Aluart. The ability to produce more efficient fabrics with less environmental impact enables us to meet the demands of the current market while reinforcing our commitment to environmental responsibility, the circular economy, and local development. At CP Aluart, we are committed to a holistic production cycle. Furthermore, this technology allows us to offer customized textile solutions, providing our clients with added value in terms of performance and functionality.

This advancement establishes us as leaders in the technical circular knit fabric sector. We are excited about the impact this circular knitting machine will have on our ability to meet the demands of an ever-evolving market.

What is circular knit fabric and why is it important?

Circular knit fabric is a type of textile created using circular knitting machines that interlace yarn loops in a continuous and uniform pattern. This process gives the fabric unique elasticity, softness, and adaptability, ideal for applications where comfort and fit are essential.

Unlike other types of knit fabric, circular knit fabric is characterized by its production in a continuous tubular form, which reduces the number of seams and improves the aesthetics and functionality of garments. This type of fabric is fundamental in sectors such as:

- Workwear: Technical clothing that combines flexibility and thermal resistance.

- Sports: Fitted garments that ensure freedom of movement and breathability.

- Fashion: Comfortable and functional clothing with modern and tailored designs.

Advantages of our new circular knitting machine

The incorporation of this new circular knitting machine enables us to take circular knit production to a new level. Key benefits include:

- Increased efficiency: Ability to produce large volumes with an unprecedented level of detail and uniformity.

- Superior quality: Greater control over fabric characteristics, ensuring each product meets the highest standards.

- Design versatility: Capability to manufacture fabrics with varying thicknesses, textures, and technical properties tailored to the specific needs of each client.

- Cost and waste reduction: Resource optimization for a more sustainable manufacturing process.