This week, CP Aluart will be exhibiting at Enforce Tac, one of the leading international…

What is circular stitch?

Circular knitting, also known as circular knitting or circular mesh knitting, is a knitting technique widely used in the textile industry. This method is characterized by the creation of seamless tubular fabrics that are ideal for a wide range of applications, from clothing to industrial products. In this article, we will explore in depth what circular stitch is, how it is done, its applications in the textile industry, and the advantages it offers.

HOW IS THE CIRCULAR STITCH MADE?

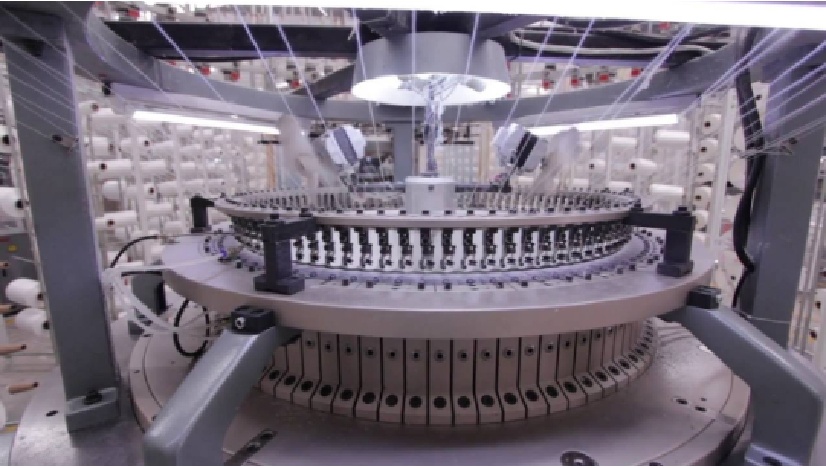

Circular knitting is carried out using a circular knitting machine. These machines can be of different diameters and configurations, but they all share the basic principle of working in a circle to form a continuous tube of fabric.

Features of circular knitting machines:

- Needles: Machines can have a variable number of needles, depending on the thickness of the thread and the type of fabric desired. The needles are arranged in a circular cylinder that rotates continuously.

- Speed: These machines are known for their high production speed, allowing large quantities of fabric to be manufactured in a short time. Some machines can produce up to 1,000 revolutions per minute.

- Versatility: They can produce a variety of knit structures, from simple knits to complex textures and patterns. Changes in needle configuration and thread type allow for a wide range of creative possibilities.

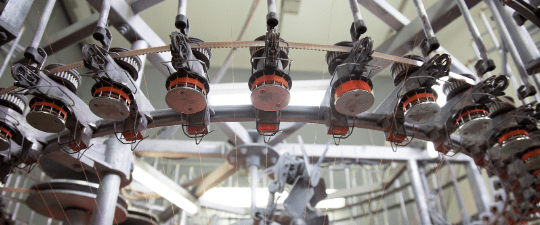

Types of circular knitting machines

There are several types of circular knitting machines, each suitable for different applications:

-

- Large diameter machines: Used to manufacture large fabrics such as sheets, blankets and certain types of clothing.

- Small diameter machines: Ideal for producing smaller, more detailed garments such as socks and sleeves.

- Jacquard machines: Allow the creation of complex and detailed patterns in the fabric.

Circular weaving process

The circular knitting process begins with the selection of the appropriate yarn, which is placed in the knitting machine. As the machine rotates, the needles lift the thread and intertwine it to form a series of continuous loops, thus creating a tubular fabric. This process can be adjusted to create different densities and textures depending on the specific requirements of the final product.

Applications of circular stitch in the textile industry

The circular stitch is extremely versatile and is used in the manufacture of different types of textile products. Some of its most common applications include:

- Underwear and Sportswear: The ability to create seamless fabrics is ideal for clothing that requires high elasticity and comfort, such as socks, tights, t-shirts and sportswear. These products benefit from softness and perfect fit to the body.

- Fashion Garments: Many designers take advantage of the versatility of the circular knit to create innovative, fitted fashion garments. Circle knit dresses, skirts and tops are popular for their modern aesthetic and comfort.

- Technical textiles: In addition to clothing, circular knitting is also used in the manufacture of technical textiles, such as filters, elastic bands, cushion covers and other industrial products. These fabrics are valued for their durability and functionality.

Advantages of circular stitch

The use of circular stitch in the textile industry offers several advantages:

- Comfort: The absence of seams in circular fabrics provides greater comfort, avoiding skin irritations. This is especially important for garments that are in direct contact with the skin for long periods.

- Elasticity: This type of fabric allows greater elasticity and adaptability, making the garments fit better to the body. Elasticity is crucial for sportswear and tight-fitting garments that require freedom of movement.

- Efficiency: Circular knitting machines are very efficient and can produce large quantities of fabric quickly, reducing production costs. This efficiency also contributes to greater sustainability in textile manufacturing.

- Design Versatility: Circular knitting machines allow for a wide range of design options, from simple patterns to complex jacquards, giving designers great creative freedom.

- Durability: Fabrics produced with circular knit tend to be more durable due to the structure of the loops, which provide resistance to wear.

Innovations in circular knitting

Circular stitch technology has not remained static. New machines and techniques are continually being developed that improve the quality and efficiency of the weaving process. Some of the recent innovations include:

- Electronic machines: Equipped with advanced software that allows precise programming of patterns and automation of design changes.

- Technical threads: Development of new types of threads that improve the properties of the fabric, such as fire resistance, antibacterial, and humidity control.

- Sustainability: Improvement in the energy efficiency of machines and the use of recycled materials to reduce environmental impact.

Circular stitch is an essential technique in the textile industry that offers numerous advantages in terms of comfort, elasticity, efficiency and design versatility. Thanks to circular knitting machines, it is possible to produce a wide variety of high-quality textile products, from underwear and sportswear to technical textiles and innovative fashion designs. If you are interested in learning more about the circular stitch and its applications, do not hesitate to contact us.